SUSTAINABILITY

ACT SUSTAINABLY

We believe our work is not just what we do but how we do it. We work ethically and efficiently to perfect performance while reusing the Earth's resources. We seek new information to develop lasting solutions. We strive to protect our planet for all who now play, and all who will play, on our home field.

Reports & Disclosures

We have built the policies, processes and structures to ensure that our teammates, suppliers and stakeholders know where we stand when it comes to ethical behavior and appropriate oversight of everything we do.

Learn More

Stakeholder Engagement

Under Armour strives to listen to all our key stakeholders and has a number of mechanisms in place to help identify and respond to potential incidents in our supply chain, including the process noted in the Reporting Potential Misconduct provision of our Supplier Code of Conduct and our participation, as a Fair Labor Association affiliate, in the FLA’s Safeguard Mechanism. When action is required, we seek to develop plans that consider local circumstances and to consider the safety of those potentially impacted, engaging third parties for support and expertise if needed. We seek to engage effectively with civil society organizations and unions representatives in key sourcing regions. For additional information, please see civil society overview related to FLA Principle 9 in Under Armour’s February 2019 FLA Accreditation Report.

More Updates from Under Armour

Under Armour and UNLESS Unveil “Pulse,” the Next Chapter in Regenerative Sportswear

Under Armour and UNLESS announce the launch of Pulse, a new regenerative apparel and footwear capsule representing the next chapter in their ongoing collaboration to rethink how sportswear is designed, worn, and returned to the earth.

Under Armour and UNLESS Introduce Three Regenerative Footwear Styles

Under Armour and UNLESS launch three new lifestyle sneakers that embody UNLESS’s regenerative ethos, inspired by nature’s circular systems, with a goal of creating not just the best sneakers in the world, but the best sneakers for the world.

Under Armour’s Celebrates 21st Annual ‘Armour Day’ with Community Service Across the City Of Baltimore

Under Armour employees come together for the purpose of community service to positively impact the brand’s hometown of Baltimore.

Under Armour and Unless Debut Regenerative Sportswear Collection at Milan Design Week

Under Armour and UNLESS spearhead a transformative shift in the sportswear industry by unveiling an innovative regenerative sportswear collection at Milan Design Week.

Significant Disparities in Sports Engagement Found Among Washington D.C. Youth

More youth in Washington D.C. play organized sports than do so nationally, but the nation’s capital faces significant participation gaps in the most impoverished neighborhoods and among Black youth and girls, according to a report released by the Aspen Institute’s Project Play initiative.

Under Armour and Curry Brand Celebrate a Good Weekend in the Bay

Under Armour and Curry Brand came together to celebrate 11-time NBA All-Star and now 2-time All-Star MVP Stephen Curry during basketball’s biggest weekend in San Francisco. With the festivities in Curry’s backyard this year, the brands showed up big time in the Bay with multiple activations, collaborations and unique product releases to show love for his legacy and remind basketball fans everywhere of their love for the game.

Curry Brand Makes Good on Community Impact Commitments

This past weekend, Curry Brand celebrated its 20th court refurbishment at McClymonds High School in Oakland, CA, fulfilling its commitment to renovate 20 safe places to play by 2025. With this final court completion, Curry Brand has officially made good on all of its community impact goals set in December 2020, renovating 20 courts, training 15,000 coaches and supporting 125 programs to ultimately impact 300,000 kids around the world.

Under Armour’s Project Rock Partners With Shepherd’s Men To Support Veterans

Many veterans return home with invisible injuries that aren’t easily understood or treated. But the SHARE Military Initiative—a comprehensive rehabilitation program for veterans with traumatic brain injuries and mental health concerns—is changing the way these wounded warriors are treated and giving them renewed hope.

Under Armour and DTLR Unveil School Spirit Rivalry Packs to Celebrate Historic Baltimore Football Tradition

In honor of the historic and iconic local rivalry between Baltimore City College and Baltimore Polytechnic Institute, Under Armour has partnered with lifestyle retailer and Baltimore community champion DTLR to co-create new school spirit Rivalry Packs. Dating back to 1889, the City vs. Poly rivalry is one of the oldest high school football rivalries in the United States, and one of Baltimore’s most highly anticipated sporting events of the year.

Under Armour’s 20th Annual ‘Armour Day’

On Thursday, September 19, 2024, Under Armour marked its 20th annual Armour Day event with volunteer activations designed to positively impact and celebrate the brand’s hometown of Baltimore.

Under Armour Basketball Celebrates Female Representation at the 2024 WNBA All-Star Weekend in Phoenix

This year at the WNBA All-Star, Under Armour made sure a group of local middle school girls got to see their potential, providing a special experience focused on female empowerment and representation alongside some of Under Armour’s most notable WNBA athletes.

Under Armour Returns to the Warrior Games for Seventh Year to Honor Military Community

Under Armour’s support for the military community knows no limits. For years, the brand has remained committed to positively impacting active-duty service members, veterans, and their families. One of the ways this comes to life is through Under Armour’s continued support of the annual Department of Defense Warrior Games.

The Future of Stretch

In 1996, Under Armour proved a single shirt can change the game forever. The brand’s original performance stretch, compression technology wicked away sweat faster than anything else out there and kept athletes cool, dry and light. Ever since, Under Armour has continued to change the game with innovative performance gear. Now, it honors its innovation heritage as it looks to the future of stretch.

Maryland Tough, Baltimore Strong

In partnership with the Baltimore Community Foundation, Under Armour has released a specially designed shirt to raise awareness and support for the short and long term needs of its community following the March 26 Key Bridge tragedy.

Curry Brand Completes 12th Court Revitalization in New York City

Curry Brand, powered by Under Armour, completed its twelfth court refurbishment at DREAM Charter School East Harlem in New York City as part of the brand’s mission to impact 100,000 youth and renovate 20 safe places to play by 2025.

Celanese and Under Armour Develop Innovative New NEOLAST™ Fiber for Use in Performance Stretch Fabrics

Celanese Corporation, a global specialty materials and chemical company, and Under Armour, Inc., a global leader and innovator in athletic apparel and footwear, have collaborated to develop a new fiber for performance stretch fabrics called NEOLAST™. The innovative material will offer the apparel industry a high-performing alternative to elastane – an elastic fiber that gives apparel stretch, commonly called spandex.

Under Armour’s Breakthrough Fiber-Shed Test Method Now Available For Industry

Following years of research in its innovation lab, earlier this year Under Armour announced a breakthrough fiber-shed test method to help address the invisible, but daunting sustainability threat microfibers and microplastics pose to society and the planet. Now, the brand has teamed up with James Heal, a leading precision testing solutions supplier, to bring its award-winning test method to life.

Under Armour Publishes FY2023 Sustainability & Impact Report

Under Armour, Inc. today published its FY2023 Sustainability & Impact Report, providing a progress update on 23 goals the company announced in 2022 as part of its work to reduce the environmental footprint of its products and operations while accelerating its social and community impact.

Welcome to the SqUAd: Diamond Miller, Laeticia Amihere, and Marina Mabrey

As the confetti settles on a record-breaking women’s college basketball season and the WNBA season tip off gets underway, Under Armour is keeping the momentum of women’s basketball on fire both on and off the court.

Under Armour and Stephen Curry Lock In Groundbreaking Partnership

Under Armour and Stephen Curry became a team in 2013. What started as an underrated point guard only a few years into the league, and a challenger brand looking to shake up the sporting industry, has become an iconic partnership with disruption and innovation at its core. Now, the two have amplified their unique partnership even further, forging a long-term commitment to serve athletes and communities and drive mutual success for years to come.

Under Armour Announces New Methodology to Measure Fiber Shedding

Under Armour, Inc. today announced it has developed a new testing methodology to help fight fiber shedding at its source and support progress toward the company's sustainability goal for 75% of fabrics in its products to be made of low-shed materials by 2030. Under Armour's innovative test method offers a simplified process to accurately measure a fabric's propensity to shed.

Introducing Dawg Class with Kelsey Plum

To pave the way for young women and show them what a future in sports can look like, Under Armour and Kelsey Plum are launching the inaugural Dawg Class. Hosted at IMG Academy in April, this mentorship program will help women college athletes navigate the transition to the professional level.

Under Armour and City Schools Celebrate Project Rampart

Today, Under Armour and City Schools celebrated Project Rampart, an ongoing six-year partnership designed to elevate the experience of City Public High School student-athletes and improve academic outcomes through the power of sports.

Under Armour Joins Ellen MacArthur Foundation, Highlights the Importance of Advancing Circularity

Embracing a circular business model is critical to the future of the planet and to the apparel, footwear, and accessories sector. By optimizing resources and working to extend the lifespan of products, companies can accomplish more with fewer inputs – effectively reducing waste and consumption to support people and the environment.

Equality Has No Offseason

At Under Armour, 'Stand for Equality' has always been a core value, meaning we stand with underrepresented groups, such as the LGBTQIA+ community, year-round and remain committed to creating better representation in sport, around the world, and in our own community.

UA Elevates the Game to Reach More HBCU Student Athletes Off the Court, Uplift Vision of Black Teammates and Voices of Community Partners

Under Armour believes that the power of sport can unite, inspire, and change the world. We are on a mission to empower the voices of our underrepresented athletes, teammates, and communities in our ongoing effort to Stand for Equality. We continue to celebrate the importance of Black History Month by delivering upon this mission.

NC State and Under Armour Partnership Takes Innovation to the Next Level

Under Armour and NC State have launched a new partnership that will support student development, commercialize research, and advance textile and materials innovation across the apparel, footwear, and accessories industry.

Under Armour Sparks Confidence in Young Female Athletes

Hype Headquarters is just one piece of Under Armour’s larger Access to Sport commitment to break down barriers and create opportunities for millions of youth to engage in sport. Through this event and future efforts, the brand has committed to increasing equity in sport by providing more youth athletes with game-changing product solutions. This event kicks off a multi-year initiative designed to help 1,200 young female athletes during its first year.

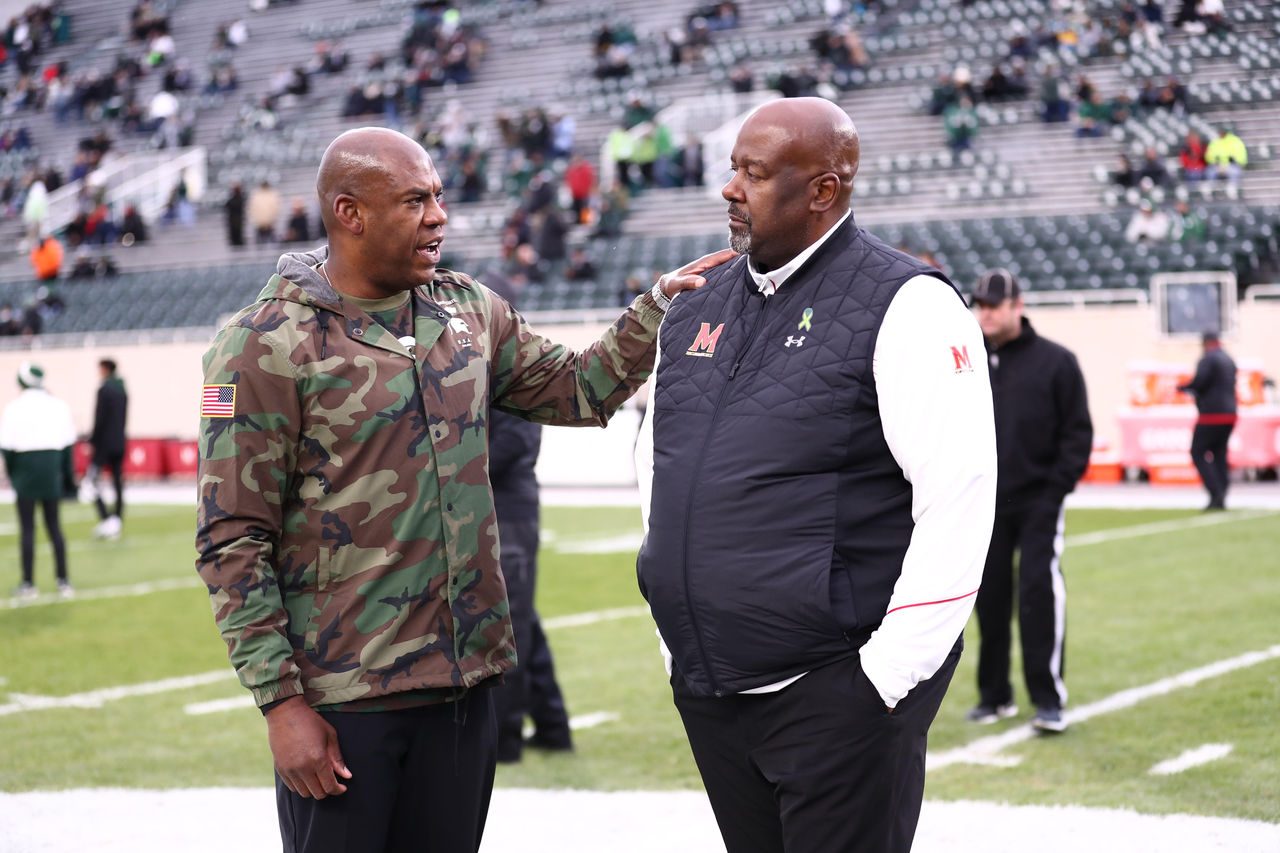

The Heartbeat of the Huddle: Empowering Minority Coaches

Diversity, equity, and inclusion are foundational to every industry. Yet these terms are almost exclusively used in corporate offices and boardrooms. While private businesses appoint board members with diverse backgrounds and create action plans, the sports world is being left in the dust.

Coalition Academy

Coaches are elemental to the success of their team and the motivation of their players. But unfortunately the playing field is far from level. Minority football players and even the fans at home don’t see themselves represented on the sidelines. That needs to change.

The All-Star No One Saw Coming

Most of the greatest successes in life and in sports are brought on by a profound change. And these big changes don’t come easily—a willingness to adapt takes bravery and determination. Finding comfort in the unknown allows us to live out our true potential instead of cowering from the next big move. Joel Embiid has allowed change to propel him forward and never let comparisons slow him down. Through the new Athlete No One Saw Coming campaign, Under Armour wants youth athletes to do the same and keep moving as they forge their own paths to greatness.

2021 Sustainability and Impact Report

Under Armour Releases 2021 Sustainability & Impact Report, Outlines New Strategic Framework, Goals, and Targets

BALTIMORE, Sept. 27, 2022 – Under Armour, Inc. (NYSE: UA, UAA) today announced the release of its 2021 Sustainability & Impact Report, outlining a new sustainability framework, goals, and targets that will guide the company’s work to reduce the environmental footprint associated with its products and operations while accelerating its social and community impact. Aligned with Global Reporting Initiative (GRI) and Sustainable Accounting Standard Board (SASB) industry standards, the report outlines 23 goals and targets designed to drive company progress across three key pillars – Products, Home Field, and Team – and underscore Under Armour’s core values, including ‘Act Sustainably’ and ‘Stand for Equality.’ “As a global innovator and leader in athletic performance apparel, footwear, and accessories, we believe Under Armour has an important role to play in addressing impending challenges facing our society, industry, and planet. This belief informs our innovation methods and compels us to rethink, reinvent, and reimagine our products and how we make them in our work to support athletes and protect people and our shared planet,” said Colin Browne, Under Armour Interim President and CEO. “Mindful that lasting change will require global cooperation across communities and industries, our new report conveys our renewed commitments to continuous improvement, industrywide collaboration, and transparent communication with our stakeholders in our ongoing sustainability journey.” Under Armour’s sustainability approach, What’s Under Matters, reflects the company’s mission to make athletes better by focusing on performance-driven innovations that utilize more sustainable materials designed for recyclability and more efficient production processes in its delivery of durable, quality, high-performing products athletes know and trust. “The details underlying a company’s sustainability strategy are foundational to its longevity and ability to generate lasting impact. For this reason, Under Armour has worked diligently over the years to finalize our approach and take concerted action before releasing this report,” said Michael Levine, Under Armour VP and Chief Sustainability Officer. “We’re pleased to share our accomplishments and perspective on our future goals, and we look forward to providing updates on our progress.” A selection of report highlights within each pillar follows: Products – Through 10 goals, the company is embracing material innovations that will enable less waste and more durability, setting the stage for circular systems by 2030, including: Prioritizing recycled and renewable materials and reducing single-use plastic brand product packaging by 75% by 2025. Implementing sustainability and circular design principles in at least half of its products by 2027 and developing chemistry and processes that can enable a circular footwear program to be launched in market, at scale, by 2030. At the end of 2021, approximately 40% of fabrics used in the company’s apparel and accessories were made from materials capable of being recycled. Supporting innovation that reduces fiber shedding from textiles and targeting 75% of fabric to be made of low-shed materials, as defined by industry-leading guidance on fabric shedding that the company will work collectively to shape by 2030. Home Field – The company is working to reduce its overall environmental footprint and do its part to protect the planet through seven goals, including: Eliminating 100% of biocides and fluorine DWR in its products by 2025. Reducing absolute scope 1, 2, and 3 greenhouse gas emissions by 30% and increasing renewable energy in owned and operated facilities to 100% by 2030. Advancing low-impact manufacturing, reducing the environmental impact of its materials, and targeting net-zero emissions by 2050. Team – The company is supporting its people and communities through six goals that build upon longstanding efforts, including: Continuing to invest in teammates' health, safety, and well-being – including through initiatives to advance diversity, equity, and inclusion and develop underrepresented talent at all levels. Protecting workers' human rights and well-being in its supply chain through comprehensive programs and audits. Working to create opportunities for millions of youth to engage in sports by 2030. To download the 2021 Sustainability & Impact Report and for further information on Under Armour’s sustainability program, visit this link. About Under Armour Under Armour, Inc., headquartered in Baltimore, Maryland, is a leading inventor, marketer, and distributor of branded athletic performance apparel, footwear, and accessories. Designed to empower human performance, Under Armour's innovative products and experiences are engineered to make athletes better. For further information, please visit http://about.underarmour.com. Forward-Looking Statements Some of the statements contained in this press release constitute forward-looking statements. Forward-looking statements relate to expectations, beliefs, projections, estimates, future plans and strategies, anticipated events or trends, and similar expressions concerning matters that are not historical facts, such as statements regarding our goals, targets, commitments, future planned initiatives and the timing and effectiveness of any of the foregoing, including those relating to the environment, human capital matters, social and labor issues, and community impact; the development and introduction of new products, technologies and ways of working; our assumptions and the implementation of our sustainability strategies; the future impacts of our investments and initiatives; and the standards and expectations of third parties. In many cases, you can identify forward-looking statements by terms such as “may,” “will,” “should,” “expects,” “plans,” “anticipates,” “believes,” “estimates,” “predicts,” “outlook,” “potential,” or the negative of these terms or other comparable terminology. The forward-looking statements contained in this press release reflect our current views about future events and are subject to risks, uncertainties, assumptions and changes in circumstances that may cause events or our actual activities or results to differ significantly from those expressed in any forward-looking statement. Although we believe that the expectations reflected in the forward-looking statements are reasonable, we cannot guarantee future events, results, actions, activity levels, performance or achievements. Readers are cautioned not to place undue reliance on these forward-looking statements. A number of important factors could cause actual results to differ materially from those indicated by the forward-looking statements, including our assumptions not being realized, scientific or technological developments, evolving sustainability strategies, evolving government regulations, and the risks and uncertainties set forth in the “Risk Factors” section of our most recent Annual Report on Form 10-K and subsequent Quarterly Reports on Form 10-Q filed with the U.S. Securities and Exchange Commission. The forward-looking statements contained in this press release reflect our views and assumptions only as of the date of this press release. We undertake no obligation to update any forward-looking statement to reflect events or circumstances after the statement's date or to reflect unanticipated events.

Curry Brand Takes Court Revitalization Efforts to Stephen’s Alma Mater

Curry Brand, powered by Under Armour, is taking on its ninth court refurbishment at the Ada Jenkins Center in Davidson, North Carolina, as part of the brand’s mission to impact 100,000 youth and renovate 20 safe places to play by 2025. The project kicked off at a special time for Stephen, as he returned to his alma mater to be inducted into the Davidson College Hall of Fame and receive his diploma. The court will be refurbished in partnership with Stephen and Ayesha’s Eat. Learn. Play. Foundation and The Summit Foundation, both of which share Curry Brand’s mission of ensuring all kids have access to safe places to play.

Under Armour Brings Together the Next Generation of Basketball Stars at Elite 24

On August 12, Under Armour hosted its Elite 24 event in Chicago, bringing together 48 of the nation’s best rising boy’s and girl’s high school basketball players. As a brand dedicated to supporting the next generation of athletes, Elite 24 provided a venue for the future’s brightest stars to showcase their skills on the national stage and rise to the ranks of the nation’s top high school performers on the court.

Stephen and Snoop Team Up for Youth Hoops

Today, more than 70 kids received the surprise of their lives when four-time NBA Champion Stephen Curry and entertainment icon Snoop Dogg unveiled a newly refurbished basketball court at the Boys & Girls Clubs of Long Beach facility in Martin Luther King, Jr. Park. While the court had spent years in need of repair, it shined during today’s unveiling as kids took to the hardwood for the first time in more than a month to engage in hands-on skills programming through the support of Curry Brand, powered by Under Armour, on its mission to impact 100,000 youth and renovate 20 safe places to play by 2025. Since the launch of Curry Brand in 2020, Stephen and Snoop have been ideating ways they could collaborate and combine their shared passion for providing access to youth sports. Over the past two years, they remained close as they brought their vision to life, utilizing their collective platforms to make a meaningful impact in the lives of others.

Curry Camp Returns to Bring Top Youth Talent Together In San Francisco

Following a two-year hiatus, Stephen Curry’s hands-on training camp returned for the top high school basketball players in the country. One of the many ways Stephen gives back to the game he loves, Curry Camp provides mentoring for elite youth basketball athletes, empowering them on their journey to compete. The four-time NBA champion personally invited 26 boys and girls from across the country to receive 1:1 coaching from the three-point king himself alongside a star-studded roster of coaches and trainers. Campers had the opportunity to show off their skills while practicing and playing with some of the sport’s best, including former Los Angeles Lakers player Kent Bazemore and recently retired Davidson College head basketball coach Bob McKillop, who also served as Stephen’s coach while at Davidson from 2006-2009.

Purpose

We empower those who strive for more.

Mission, Vision and Values

Our Values define and unite us, the beliefs that are the red thread that connect everyone at Under Armour. Our values are rallying cries, reminding us why we’re here, and fueling everything we do.

Outward Bound Partners with Lt. Richard W. Collins III Foundation, Under Armour for Three-Year Program with Maryland Universities

Eleven Reserve Officer Training Corp (ROTC) cadets from University of Maryland (UMD), College Park and Bowie State University (BSU) completed their five-day wilderness expedition on Friday, June 10. The expedition took the participants along a stretch of the Appalachian Trail with their Outward Bound educators. The week-long challenge was the final step in the first year of the Building Bridges program that brought together over 40 cadets from the two schools, starting with a one-day program held in September 2021 at Chesapeake Bay Outward Bound School’s (CBOBS) Leakin Park campus. The program is sponsored by Under Armour, through its UA Freedom Initiative, which focuses on supporting front-line workers, like ROTC cadets. “This was an experience of a lifetime. I took so many lessons and so much about myself. I learned and recognized that it’s okay to fall sometimes. It’s about what you do after. Getting back up and not allowing your setbacks to stop you from pushing forward. I learned so much about allowing yourself to work with others, trusting them along with yourself, and the difference it all makes in the end,” shared Kayla, an ROTC cadet from Bowie State University after completing the five-day expedition with their crew.

Creating a Legacy Starts at Home

Aliyah Boston is one of the country's most talented and recognizable basketball players. She has come a long way from her makeshift driveway basketball court in St. Thomas, but that doesn’t mean she’s left the islands in her past. Earlier this month, Aliyah crossed yet another milestone off her list by hosting her first UA Next Basketball camp in her hometown in the Virgin Islands. Created to educate, empower and encourage athletes of all ages, backgrounds, skill and socioeconomic levels—especially youth athletes—to get out and get moving, Under Armour’s UA Next platform launched in 2021 and has since expanded to cover several team sports categories.

Bringing Purpose to Student-Athlete Partnerships

In 2021 the relationship between brands and student-athletes changed forever with the move to allow students to profit off of their name, image, and likeness (or NIL), in addition to making money from signing autographs, starting their own businesses, teaching camps or lessons, starring in advertising campaigns and posting sponsored social media content. Before this landmark decision, critics claimed for decades that compensating student-athletes would make it harder for them to focus on competition and schooling. Instead, athletes have found the new rules are not only lucrative but liberating. Now, on the first anniversary of this significant shift, Under Armour reflects on its successful roster of purpose-first, NIL partnerships and outlines its future goals for this new frontier of collegiate sports marketing.

Newsweek Recognizes Under Armour on Most Trustworthy Companies 2022 List

Trust builds great athletes, and trust runs deep at Under Armour. From trusting yourself to go the extra mile to trusting your teammates to step in when you need support, trust unites us and helps us Strive for More. Newsweek has recognized Under Armour in their inaugural Most Trustworthy Companies 2022 list. In partnership with Statista, a German company specializing in marketing and consumer data, Newsweek ranked Under Armour #2 out of 16 total companies for the Textile, Clothing, & Luxury Goods category. “Each and every teammate at Under Armour plays a role in bringing our purpose to life,” said Under Armour CEO Patrik Frisk. “Being recognized as one of America’s Most Trustworthy Companies speaks volumes to the passion and integrity our teammates bring forward in everything they do in both their professional and personal lives.” With help from a survey of 50,000 U.S. residents, companies were evaluated across different elements related to customer, investor, and employee trust. Survey respondents answered questions about how companies engaged customers and treated their employees. Publicly traded U.S. corporations with $500 million or more in annual revenues made the list. Newsweek reviewed companies aligning to 22 industries, ranging from Banks, Energy & Utilities, Health Care & Life Sciences, and more. Insights from the 2022 Edelman Trust Barometer showed how employee trust is the number one driver of trust. More specifically, many employees expect their employer to engage on societal issues and provide quality information. Under Armour’s ongoing and tangible actions to address issues like economic equality and community policing relationships are felt across the business. As Under Armour continues to put its purpose at the forefront of all activities, the business will continue to make decisions grounded in doing what is right for their consumers instead of solely responding to the market and reacting to competitors. Under Armour is committed to empowering those who strive for more, and the company’s values – Act Sustainably, Celebrate the Wins, Stand for Equality, Love Athletes and Fight on Together – serve as both a checklist for each of our programs and the qualities expected of every teammate.

Curry Court 007: Australian Basketball Court Gets a Curry Brand Makeover

Under Armour is committed to breaking down barriers all over the world that keep young people from accessing sports and sports education. That’s why we set out to “Change the Game for Good,” an ongoing initiative from Curry Brand aimed at creating opportunity, access, and equality for youth sports in neighborhoods around the world. In service of this mission, Curry Brand has proudly forged a partnership with Charity Bounce — an Australian organization that uses sports, the arts, and education to uplift disadvantaged communities, with a particular focus on Aboriginal or Torres Strait Islanders and culturally diverse communities, including newly arrived refugees. Using the power of sport, Charity Bounce inspires change, builds resiliency, and creates positive job opportunities for young people at risk. As part of this partnership, Curry Brand has committed to rejuvenating youth facilities in Arncliffe New South Wales, Australia that are used for Charity Bounce programs — making it the first official Curry Brand basketball court outside of the United States. “We are thrilled to partner with a purpose-led performance brand,” said Charity Bounce CEO Ian Heininger. “The new court will provide inspiration for the young athletes across our programs to look beyond themselves and use the game for good. This initiative will not only encourage them to be their best, but our ambition is also that it will create a lasting impact on their sense of worth and increase their expectation of what is possible in life. Stephen Curry has one of the most inspiring stories of resilience, and we know this partnership will be a critical piece in empowering every young person that now steps on the court.”

Creating More Access to Sport for The Next Generation of Athletes

At Under Armour, we know sport is so much more than a game. It inspires collaboration and teamwork, increases confidence, reduces stress and improves mental health. But around the world today, millions of young people are facing barriers that are negatively impacting their journey to compete – from a lack of funding, time or transportation, to social and mental hurdles that make children feel they don’t belong on a team. In the United States, participation in sports has rebounded since the start of the pandemic, but many organized outlets have not yet come back. One study found that as a result, 3 in 10 kids who played organized sports before the pandemic have lost interest in doing so. Outside the United States, many lack access to public resources that could get them competing. And in every region and demographic group, children from lower-income families spend less time playing sports. Under Armour believes everyone deserves the right to engage in sport. That’s why we are making a new, long-term commitment of our resources, focus and energy to help break down barriers that limit access to sport across the globe.

To Baltimore with Love

This is a love letter. To a city that redefines resiliency. To the beauty and strength of the Black community that has so much to offer. To the connection and possibilities that sports bring.

As Young Athletes Struggle To Compete During Pandemic, Under Armour Makes Sure They Can Still Play Responsibly

Coronavirus may have shut down competition for young athletes, but Under Armour wants to ensure they can still play. That’s why this fall, the company is continuing to invest in young athletes and providing them with a performance mask – a training necessity in today’s pandemic environment that often runs a higher price than generic masks currently in the market and may be unattainable for many young athletes. The company announced that, in partnership with pro athletes, it will donate more than 35,000 UA SPORTSMASKs to young athletes dealing with the effects of the pandemic in cities like Oakland, Nashville, Baltimore and others around the world. The UA SPORTSMASK, which launched earlier this summer, is the first to be designed for athletes to train in with innovative technology to keep them cool and comfortable while being active.

A STORE FOR ALL ATHLETES

As the Human Performance Company, Under Armour is delivering on its mission to make all athletes better through a new retail store experience. The UA Brand House City Concept delivers an elevated store design, experiential touchpoints and product and service offerings that provide athletes with new ways to interact with the brand unique to the in-store experience. More than 18 months in the making, Under Armour put the concept to the test, listening and leveraging insights from its Focused Performer consumer to inform the retail expression.

Leaning in to Stop the Spread

For 24 years, Under Armour has pushed the limits of the world of sports performance with product innovations developed to make all athletes better. Last week, the brand began putting that experience to work helping health care systems defend against the coronavirus pandemic. To support the University of Maryland Medical System’s (UMMS) 28,000 health care providers and staff, Under Armour has begun to manufacture and assemble face masks, face shields and specially equipped fanny packs, and is also exploring fabricating hospital gowns for the statewide medical system. The brand will also begin providing face masks to LifeBridge, a regional health care organization based in Baltimore. Additionally, Under Armour is currently discussing the needs for supplies with Johns Hopkins Medicine, MedStar and other local medical institutions. "When the call came in from our local medical providers for more masks, gowns and supply kits, we just went straight to work," said Randy Harward, SVP of Advanced Material and Manufacturing Innovation at Under Armour. “More than 50 Under Armour teammates from materials scientists to footwear and apparel designers from laboratories in Baltimore and Portland quickly came together in search of solutions.”

Winning at the Game of Life

The true scrimmage line is off the field for many Baltimore City student-athletes. Too often, it’s a game of high stakes and low expectations. On the other side of doubt, there’s a team working hard to change negative perceptions around Baltimore City schools. Project Rampart, which began in 2017, is UA’s commitment to elevating the Baltimore student-athlete experience. “When we invest in apparel, equipment and facilities, provide professional development for coaches, and support student academic and leadership experiences, we empower student-athletes to reach their full potential,” says Stacey Ulrich, Under Armour's Senior Director of Global Philanthropy and Community Outreach.

These Teens Mean Business

The story of Under Armour’s start-up success is a well-known representation of the American Dream of entrepreneurship – a dream that is alive and well in today’s youth. In fact, a survey of 500 teens conducted by Junior Achievement (JA) and ORC International found that 87 percent of high school students want to start a business someday. With guidance from UA teammates, some innovative students are getting the chance to do just that. Twelve Baltimore City high school students are the brains behind Creators 4 Change, a non-profit developed as part of Junior Achievement of Central Maryland’s JA Company Program, a 15-week entrepreneurship experience that gives students a chance to start and run their own businesses backed by real investors and revenue. The group meets weekly on Under Armour’s campus to discuss business strategies with UA teammates, who serve as volunteer mentors.

WHEN "WILL" MEANS SERVICE

Study after study has shown that the physical environment of a school has a significant impact on the quality of a student’s education. In Baltimore City, due to a multitude of circumstances, there are many schools that are in need of updated facilities but lack in resources and funding. Seeing this need, Under Armour has partnered with the Heart of America Foundation to identify schools to transform and renovate. Now in its third year, Under Armour and the Heart of America Foundation completed its annual Week of WILL – a week of volunteerism and giving back to the city, all rooted in the brand’s ongoing commitment to the Baltimore community.

Transforming Students’ Lives Through Sport

The transformative nature of sport, beyond the wins and the losses, can often be overlooked and underappreciated. With that in mind, in 2016 Under Armour pulled together a team to understand the needs of Baltimore City Public Schools (BCPS) students in the company’s backyard, with the goal of enriching the lives of every student-athlete throughout the school district. As a result the Baltimore Student Athlete Coalition was formed by Under Armour, the Baltimore Ravens, the InSideOut Initiative and the Fund for Educational Excellence to use the power of sports to transform the lives of student athletes throughout BCPS while promoting more equitable access to enriching activities, particularly sports. This fall, the power of that partnership takes shape for the second straight school year as students, teachers and coaches begin the 2018/19 school year. “Successful schools provide opportunities for students to explore their interests, with enriching activities both in and out of the classroom. They also create positive cultures where students have the confidence to explore those opportunities,” said Dr. Sonja Brookins Santelises, BCPS chief executive officer. In 2017, BCPS launched a blueprint (www.baltimorecityschools.org/blueprint) that lays out how the district will build a generation of young people with the skills, knowledge, and understanding to succeed in college, careers, and community. Addressing the holistic needs of the student, including physical activity, was a critical component. Professional development for athletic directors and coaches that began in the summer of 2017, being led by the InSideOut Initiative, is being put into action as student-athletes return to school and on fields of play this fall. The program promotes sports as a human growth experience and aims to create an environment where sports are education-based, ultimately becoming co-curricular rather than extra-curricular.

Run to Vote

Project Rampart

Under Armour’s city-wide commitment to inspiring and investing in Baltimore City athletics to help elevate opportunity and access to sports for students. Through this commitment Baltimore City Public High Schools’ athletic facilities will be upgraded, students and coaches are equipped with new on-field performance apparel, student athletes will receive leadership development, and coaches will receive training through specialized programing.

Impact

We envision a world in which all youth have access and opportunity to play sport.

Culture

Under Armour believes that the power of sport can unite, inspire, and change the world.

Partners